Industrial companies often face challenges in controlling and optimizing their processes. Lack of access to or poor quality of production data, leads to costly downtime and losses. Our implemented solutions within SCADA systems effectively eliminate these difficulties, providing full operational capability, rapid response and full insight into current and historical process data.

SCADA systems

SCADA as the name “Supervisory Control and Data Acquisition” indicates,

is a system that allows remote control and collection of production data.

Find out how we can support your business

Problems and challenges

No real-time insight

Lack of process data makes it impossible to control the quality of the process. SCADA systems, by monitoring operations in real time, allow rapid detection and resolution of problems.

Central management

Managing large and distributed industrial systems can be difficult. SCADA integrates all operations into a single system, providing remote control and monitoring from a central point, simplifying management.

Too slow response to failures and deviations

Delays in identifying problems can lead to a decline in product quality, as well as machine and plant failures and downtime. The use of SCADA enables continuous control and immediate response to any deviations.

Step by Step

When implementing SCADA systems, we provide a comprehensive approach at every stage of implementation. From needs analysis, design and integration to training and technical support, our team makes sure that the solutions are fully customized to your specific business.

Competitive Advantage

We are part of the renowned Transition Technologies Group, which has been creating the future of industrial technology since 1991. The group includes 21 companies, employs more than 2,280 specialists and operates from 27 offices around the world, operating with 100% Polish capital. Our mission is to provide innovative technology solutions that drive global industry growth.

- Innovation: We constantly invest in the latest technologies to keep our solutions at the forefront of innovation.

- Experience: More than three decades in the industrial technology market provide us with the knowledge and skills needed for the most demanding projects.

- Quality: We are ISO 9001:2015, ISO 27001:2013 and ISO 45001:2018 certified, confirming our commitment to the highest standards of quality and safety.

When you choose our solutions, you are investing in the future of your business – a future that is innovative, efficient and sustainable.

We work with the best:

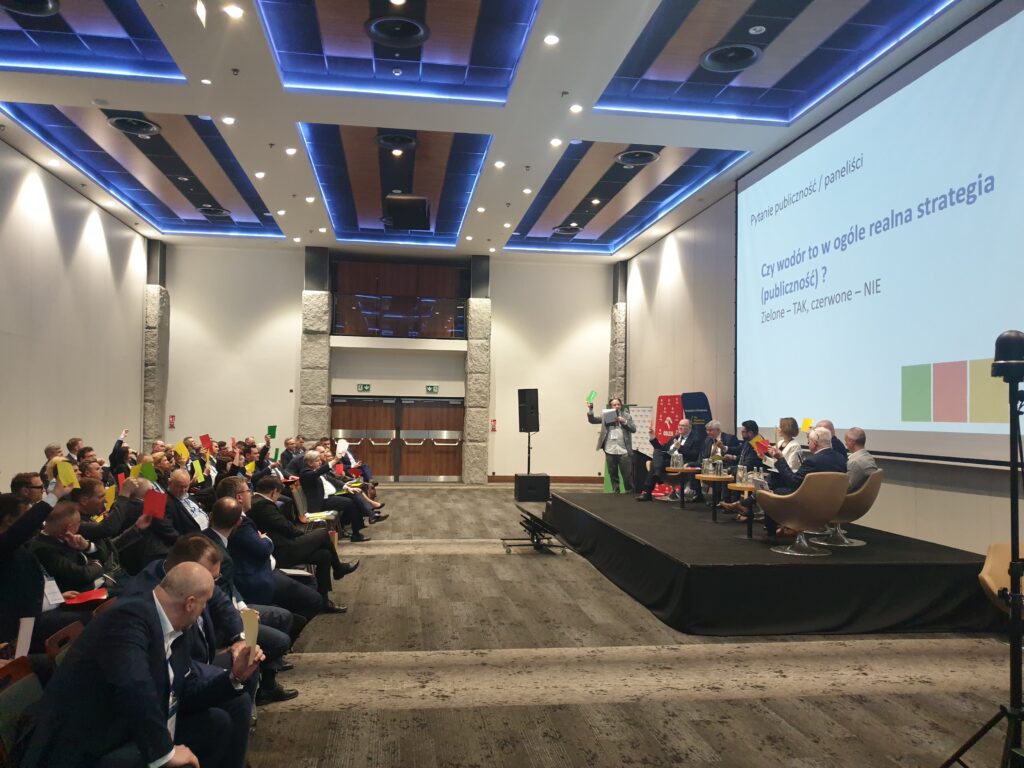

Opinions of Our Customers

”From the very beginning of our cooperation, Transition Technologies-Control Solutions has made itself known as a reliable partner. What set them apart was their creative approach at the bidding stage. We were presented with several proposals for solutions based on which we could choose a target direction.</p>

Adam BombaProcess Manager

<p>During implementation, on the other hand, they acted with determination, solving successive problems that arose. Faced with the fact that the project was implemented in a difficult market environment, we often had to work together and develop remedies, often through compromise. Also, during the operation of the site, they reacted constructively and quickly to faults as they appeared.</p>

<p>TT-CS has proven itself as a trusted partner in challenging projects. We positively look forward to working together on future mechanical engineering projects.

Our experts guarantee the quality of services

He graduated from the Wroclaw University of Technology, majoring in automation and robotics, and from the University of Wroclaw and Lodz, where he studied Computer Science.

He has been with Transition Technologies Group since 2008, and has actively participated as a solution integrator in many projects around the world, in the field of industrial automation in the energy sector.

Since 2022, he has been the Director of Industrial Automation. strategic projects. He is responsible for the implementation of key projects for the company, mainly in the energy and Gas & Oil sectors at Transition Technologies-Control Solutions.

He is a graduate of Wroclaw University of Technology, where he completed his master’s degree in Automation and Robotics at the Faculty of Electronics, and Wroclaw University of Economics, where he completed postgraduate studies in Project Management. He has been an active engineer since 2011, focusing his interests in the area of process automation. He has been with Transition Technologies Group for more than five years, serving as an engineer and designer (instrumentation and control systems).

Since 2022, he has served as Manager in the Strategic Projects Department at Transition Technologies-Control Solutions.

He is a member of PIME. He holds Prince2 certification, which confirms his competence in managing large projects.

Its portfolio boasts a number of projects on strategic facilities and for critical infrastructure, including. leading the ACP work on the construction of Baltic Pipe.

He is currently expanding his knowledge and competence in the area of functional safety and hazard analysis.

A graduate of Kielce University of Technology, where he majored in Environmental Engineering at the Faculty of Construction and Environmental Engineering. His entire career has been in the technical industry, where he effectively combines engineering knowledge with business and interpersonal skills to support sales processes for technology and engineering solutions.

To grow in the field of industrial automation, he joined the TT-CS team. He is passionate about aquariums and terrariums, creating and nurturing complex ecosystems for aquatic and exotic animals. His hobby requires precision and patience, which is reflected in his professional approach to his work

A graduate of Wroclaw University of Technology, where he graduated in 1990 with a degree in Electron Technology from the Department of Electronics. He began his career as an assistant designer at the “Record” Automation Systems Company.

He has been with Transition Technologies Group for more than 26 years.

For more than 12 years, he has served as Project Manager at Transition Technologies-Control Solutions.

In his role, he manages the implementation of industrial automation projects.

We Are Here to Help

Are you interested in our offer?

Write to us for a personalized consultation.

- Individual counseling

- Tailored solutions

- Quick implementation

- Experts with experience

Fill out the form and get a free consultation

Questions

and answers

In the FAQ section, you will find answers to key questions about our services and processes, based on knowledge and experience. Our goal is to dispel doubts and provide clear information.

What are SCADA systems and what are they used for?

SCADA (Supervisory Control and Data Acquisition) systems are integrated platforms for remote monitoring and control of industrial processes. They enable real-time data collection, analysis and task automation, providing full control of operations from one central point. SCADA is used in a variety of industrial sectors, such as energy, manufacturing, water utilities and other industries requiring precise process management.

What are the benefits of implementing a SCADA system?

SCADA systems provide a complete view of operational processes in real time, enabling rapid response to any deviations and potential problems. Benefits include reduced downtime, improved process efficiency, remote monitoring, automation of emergency response and the ability to plan for the long term based on collected data. With SCADA, companies can significantly optimize their operations, saving time and costs.

In what industries are SCADA systems most commonly used?

SCADA is widely used in industries where large-scale process monitoring and management is crucial. Major sectors include power generation (electrical grid management), manufacturing (production line automation), water and wastewater (water flow monitoring), oil and gas (production and transportation control), and infrastructure management systems such as transportation and traffic management.

Can SCADA systems be integrated with other technologies?

Yes, SCADA systems are highly flexible and can be integrated with other automation systems such as PLCs, DCS (Distributed Control Systems) and IoT (Internet of Things) technologies. This integration allows for even more advanced management and monitoring, supporting both day-to-day operations and long-term company goals. SCADA systems can also interface with databases and ERP systems for better resource planning.

What is the process of SCADA system implementation?

The process of implementing a SCADA system involves several stages: starting with an analysis of the customer’s needs, through design, integration with existing infrastructure, to installation and staff training. Once the system is implemented, we provide technical support and ongoing monitoring to ensure that the system operates effectively and is adapted to changing operational needs.

How does SCADA support operational security?

SCADA systems play a key role in ensuring operational safety. They enable early detection of abnormalities, such as equipment failures or deviations in process parameters, so that operators can respond quickly, minimizing the risk of downtime and safety hazards. SCADA also supports remote monitoring and automatic alarming, helping to improve the safety of the entire plant.