Robotics and Mechanical Engineering

We offer a range of services related to the automation and robotization of production processes. We deal with all stages of the creation of automated workstations: mechanical design, mechanical and electrical assembly, PLC programming, configuration of servo and other actuators, design of electrical and pneumatic circuits, programming of industrial and collaborative robots, as well as service and training.

We offer solutions that fit the vision of Industry 4.0 – advanced vision systems, IoT devices, cobots, as well as devices and software created from scratch with a specific application in mind.

The project implementation methodology we use involves the user in co-creating solutions at every stage of the process. We focus on open communication and proactivity in solving emerging challenges.

Why should you work with us?

-

Expert Knowledge and Experience

As a leader in industrial robotics, we have extensive experience in designing and implementing systems with collaborative robots. Our team is made up of highly skilled engineers who understand the specific needs of your industry.

-

A Comprehensive Approach

We provide full service – from analysis and design, to implementation, to testing and staff training. This ensures that each implementation is fully customized to your production needs.

-

Safety First

Our cobots are designed to work safely with humans. We ensure the highest safety standards, which minimizes risk and protects your employees.

-

Flexibility and Scalability

Our solutions are flexible and can be easily adapted to changing production needs, providing scalability and ease of integration.

-

Increase Productivity and Precision

Cobots increase production efficiency, reducing errors and downtime. They perform complex tasks with high precision, improving product quality and reducing operating costs.

-

Innovative Technologies

We work with leading manufacturers such as Doosan Robotics to offer the latest technologies in collaborative robotics. Our cobots are technologically advanced and intuitive to use.

-

Long-term Support and Service

We provide full after-sales support, including service and system optimization, guaranteeing the reliability of cobots for many years.

-

Cooperation based on Partnership

We build long-term relationships based on trust. We execute each project with the goal of delivering solutions that exceed expectations.

Certifications and Compliance

Our work is guided by the highest standards, which is why all of our services and solutions comply with international cyber security standards and regulations. Our certifications include:

- ISO 27001 – An information security management standard that ensures that your data is protected according to the highest requirements.

- NIST Cybersecurity Framework – A security framework that ensures effective management of cyber threats.

- IEC 62443 – International standard for the safety of industrial automation and control systems.

In addition, we ensure that our solutions comply with local regulations, which is crucial for companies operating in regulated sectors such as energy, chemicals and critical infrastructure.

Competitive Advantage

We are part of the renowned Transition Technologies Group, which has been creating the future of industrial technology since 1991. The group includes 21 companies, employs more than 2,280 specialists and operates from 27 offices around the world, operating with 100% Polish capital. Our mission is to provide innovative technology solutions that drive global industry growth.

- Innovation: We constantly invest in the latest technologies to keep our solutions at the forefront of innovation.

- Experience: More than three decades in the industrial technology market provide us with the knowledge and skills needed for the most demanding projects.

- Quality: We are ISO 9001:2015, ISO 27001:2013 and ISO 45001:2018 certified, confirming our commitment to the highest standards of quality and safety.

When you choose our solutions, you are investing in the future of your business – a future that is innovative, efficient and sustainable.

Facts that speak for themselves

in Europe

Rozwiązania dla branż

Rozwiązania dla branż

Rozwiązania dla branż

Rozwiązania dla branż

Rozwiązania dla branż

Step by Step

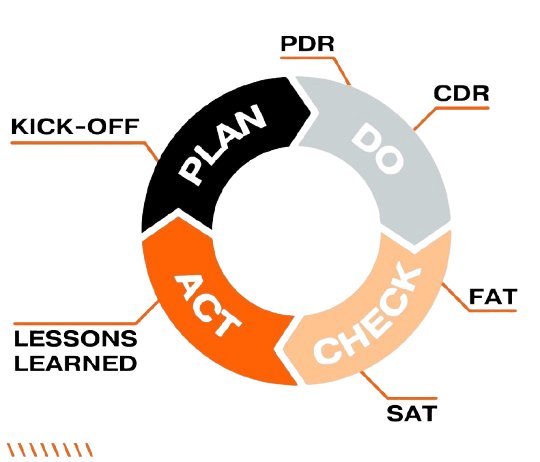

Deeply rooted in our DNA is a culture of continuous improvement reflected in the process of delivering value to our customers. We use the PDCA methodology in practice. Plan, Execute, Check and Revise – these are the stages into which we have written typical milestones in our projects.

Opinions of Our Customers

”

From the very beginning of our cooperation, Transition Technologies-Control Solutions has made itself known as a reliable partner. What set them apart was their creative approach at the bidding stage. We were presented with several proposals for solutions based on which we could choose a target direction.

During implementation, on the other hand, they acted with determination, solving successive problems that arose. Faced with the fact that the project was implemented in a difficult market environment, we often had to work together and develop remedies, often through compromise. Also, during the operation of the site, they reacted constructively and quickly to faults as they appeared.

TT-CS has proven itself as a trusted partner in challenging projects. We positively look forward to working together on future mechanical engineering projects.

Adam BombaProcess Manager

Our team

Director of the robotics area at Transition Technologies-Control Solutions. A mechanical engineer by training and passion.

He has many years of experience in manufacturing process automation and project management. With the company for 3 years, he is currently in charge of business development of the robotics department and coordinating its work.

Project coordinator at Transition Technologies-Control Solutions. A mechanical engineer by training with a DIY vein.

He has extensive experience in process management. Performs tasks in automation and robotics projects.

Automation engineer at Transition Technologies-Control Solutions, a graduate of the Faculty of Mechanical Engineering at Wroclaw University of Technology.

He has been professionally involved in industrial automation for 5 years. Performs tasks in robotics and mechanical engineering projects.

We Are Here to Help

Are you interested in our offer?

Write to us for a personalized consultation.

- Individual counseling

- Tailored solutions

- Quick implementation

- Experts with experience

Fill out the form and get a free consultation

Questions

and answers

In the FAQ section, you will find answers to key questions about our services and processes, based on knowledge and experience. Our goal is to dispel doubts and provide clear information.

What are cobots and how do they differ from traditional industrial robots?

Cobots, or collaborative robots, are designed to work safely side-by-side with humans. Unlike traditional industrial robots, which often require separate, fenced-off work zones, cobots can work in direct contact with operators, increasing the flexibility and safety of manufacturing processes.

What are the main benefits of implementing cobots?

Cobots increase production efficiency and precision while reducing operating costs. They are flexible, easy to program and can be quickly adapted to different tasks, making them ideal for dynamically changing production needs.

Can cobots work with existing production lines?

Yes, cobots are designed to integrate easily into existing production lines. We offer full support for integrating cobots into your infrastructure, ensuring a smooth transition and minimal downtime.

What are the safety requirements when using cobots?

Safety is our top priority. Cobots are equipped with advanced security systems that protect operators from unforeseen events. In addition, our solutions comply with international safety standards, which minimizes the risks associated with their use.

What is the process of implementing cobots?

The implementation process includes detailed analysis, bench design, installation, programming, testing and staff training. We provide full support at every stage to ensure that the implementation goes smoothly and according to plan.

What industries can benefit from collaborative robotics?

Cobots are used in a wide range of industries, such as automotive, electronics, food, pharmaceutical and many others. They are ideal for both small and large companies that want to increase the efficiency and flexibility of their production processes.

Do you offer cobot training?

Yes, we offer comprehensive training for your team that covers both theoretical and practical aspects of cobot operation. The trainings are tailored to the participants’ level of knowledge and experience, ensuring that they are fully ready to work with the new systems.

What support do you offer after cobots are deployed?

After deployment, we provide full after-sales support, including service, regular maintenance and system optimization. We are available to help with every aspect of cobot operation so that your systems run reliably for a long time.