–

Industrial robots

We commonly use this type of actuators in many different processes. Our robotics engineers have experience working with robots from manufacturers such as Kawasaki, Fanuc, Kuka, ABB, Omron, Epson, Doosan, Universal Robots and others.

Find out how we can support your business

Choosing the right robot

Choosing the right robot for a given application is the key to a successful implementation. Without this, it may not be possible to achieve the required functionality, the machine’s performance parameters may suffer, and in extreme cases damage may occur – these are just a few examples. To prevent this, we perform a series of simulations in an offline environment to verify assumptions. Behind the process are experienced engineers who comprehensively analyze the requirements and also take into account less obvious aspects such as ATEX, dust and the way the robot is assembled.

Security

Any machine (or set of machines) must, above all, be safe. The emphasis on this aspect is steadily increasing. This is influenced by factors such as the developing organizational culture of companies, the increasing number of legal requirements and restrictions, as well as the declining social acceptance of non-compliance with occupational health and safety. Industrial robots are components. Only their integration with other components creates a system. Even if they are equipped with integrated safety systems, such as Cubic-S (Kawasaki) or DCS (Fanuc), for example, without a properly conducted risk assessment and conformity assessment (CE) process, they will not effectively ensure user safety.

Necessary competencies during operation

Deployment of a machine is usually only the beginning of the process of long-term operation. For it to be possible, attention to technical condition is necessary. The correctness of maintenance and the competence behind it is a key value. Long-term operation also means that there is often a need for modernization or adaptation to new products and functionality. In this case, the ability to program industrial robots is essential. It is our value to build long-term partnerships with our customers, so in addition to a package of implementation training – provided by us or together with partners – we provide support and readiness for the development of implemented machines.

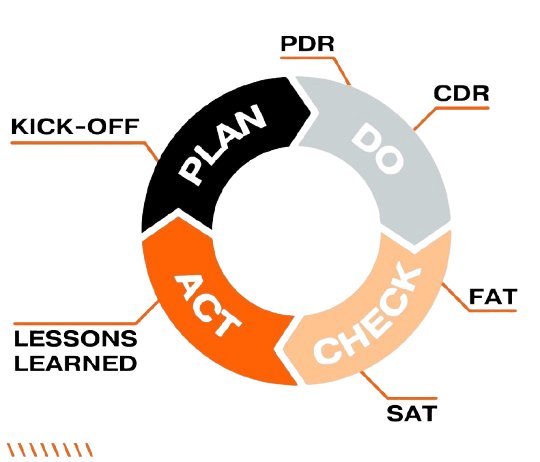

Step by Step

Deeply rooted in our DNA is a culture of continuous improvement reflected in the process of delivering value to our customers. We use the PDCA methodology in practice. Plan, Execute, Check and Revise – these are the stages into which we have written typical milestones in our projects.

Competitive Advantage

We are part of the renowned Transition Technologies Group, which has been creating the future of industrial technology since 1991. The group includes 21 companies, employs more than 2,280 specialists and operates from 27 offices around the world, operating with 100% Polish capital. Our mission is to provide innovative technology solutions that drive global industry growth.

- Innovation: We constantly invest in the latest technologies to keep our solutions at the forefront of innovation.

- Experience: More than three decades in the industrial technology market provide us with the knowledge and skills needed for the most demanding projects.

- Quality: We are ISO 9001:2015, ISO 27001:2013 and ISO 45001:2018 certified, confirming our commitment to the highest standards of quality and safety.

When you choose our solutions, you are investing in the future of your business – a future that is innovative, efficient and sustainable.

We work with the best:

Opinions of Our Customers

”From the very beginning of our cooperation, Transition Technologies-Control Solutions has made itself known as a reliable partner. What set them apart was their creative approach at the bidding stage. We were presented with several proposals for solutions based on which we could choose a target direction.</p>

Adam BombaProcess Manager

<p>During implementation, on the other hand, they acted with determination, solving successive problems that arose. Faced with the fact that the project was implemented in a difficult market environment, we often had to work together and develop remedies, often through compromise. Also, during the operation of the site, they reacted constructively and quickly to faults as they appeared.</p>

<p>TT-CS has proven itself as a trusted partner in challenging projects. We positively look forward to working together on future mechanical engineering projects.

Our team

Director of the robotics area at Transition Technologies-Control Solutions. A mechanical engineer by training and passion.

He has many years of experience in manufacturing process automation and project management. With the company for 3 years, he is currently in charge of business development of the robotics department and coordinating its work.

Project coordinator at Transition Technologies-Control Solutions. A mechanical engineer by training with a DIY vein.

He has extensive experience in process management. Performs tasks in automation and robotics projects.

Automation engineer at Transition Technologies-Control Solutions, a graduate of the Faculty of Mechanical Engineering at Wroclaw University of Technology.

He has been professionally involved in industrial automation for 5 years. Performs tasks in robotics and mechanical engineering projects.

We Are Here to Help

Are you interested in our offer?

Write to us for a personalized consultation.

- Individual counseling

- Tailored solutions

- Quick implementation

- Experts with experience