A number of challenges and issues can arise in machinery modernization projects that require engineers and project managers to plan precisely, be flexible and communicate well with the client. This allows us to minimize risks and achieve the desired results.

Machine upgrades

Find out how we can support your business

Problems and challenges

Technical complexity and integration with existing systems

Upgrading existing machines requires complex integration of new components with existing, often older systems. Differences in technologies, communication protocols or standards can make it difficult to synchronize all components seamlessly, often requiring customized solutions.

Meet standards and regulations, including CE

Upgraded machines must comply with applicable standards and regulations, including those related to safety and CE compliance. The challenge is to re-analyze risks and verify that modifications do not violate technical requirements, which may require additional testing and certification.

Cost, schedule and minimize downtime

Managing budget and lead time is key in modernization, especially in the context of unforeseen technical problems. Additionally, an important challenge is to minimize production downtime so as not to disrupt plant operations.

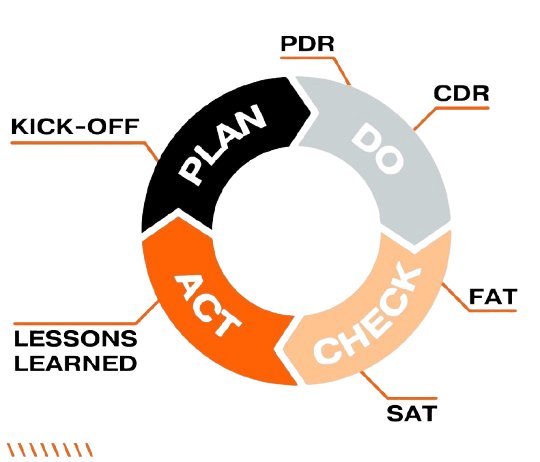

Step by Step

Deeply rooted in our DNA is a culture of continuous improvement reflected in the process of delivering value to our customers. We use the PDCA methodology in practice. Plan, Execute, Check and Revise – these are the stages into which we have written typical milestones in our projects.

Competitive Advantage

We are part of the renowned Transition Technologies Group, which has been creating the future of industrial technology since 1991. The group includes 21 companies, employs more than 2,280 specialists and operates from 27 offices around the world, operating with 100% Polish capital. Our mission is to provide innovative technology solutions that drive global industry growth.

- Innovation: We constantly invest in the latest technologies to keep our solutions at the forefront of innovation.

- Experience: More than three decades in the industrial technology market provide us with the knowledge and skills needed for the most demanding projects.

- Quality: We are ISO 9001:2015, ISO 27001:2013 and ISO 45001:2018 certified, confirming our commitment to the highest standards of quality and safety.

When you choose our solutions, you are investing in the future of your business – a future that is innovative, efficient and sustainable.

We work with the best:

Opinions of Our Customers

”From the very beginning of our cooperation, Transition Technologies-Control Solutions has made itself known as a reliable partner. What set them apart was their creative approach at the bidding stage. We were presented with several proposals for solutions based on which we could choose a target direction.</p>

Adam BombaProcess Manager

<p>During implementation, on the other hand, they acted with determination, solving successive problems that arose. Faced with the fact that the project was implemented in a difficult market environment, we often had to work together and develop remedies, often through compromise. Also, during the operation of the site, they reacted constructively and quickly to faults as they appeared.</p>

<p>TT-CS has proven itself as a trusted partner in challenging projects. We positively look forward to working together on future mechanical engineering projects.

Our team

Director of the robotics area at Transition Technologies-Control Solutions. A mechanical engineer by training and passion.

He has many years of experience in manufacturing process automation and project management. With the company for 3 years, he is currently in charge of business development of the robotics department and coordinating its work.

Project coordinator at Transition Technologies-Control Solutions. A mechanical engineer by training with a DIY vein.

He has extensive experience in process management. Performs tasks in automation and robotics projects.

Automation engineer at Transition Technologies-Control Solutions, a graduate of the Faculty of Mechanical Engineering at Wroclaw University of Technology.

He has been professionally involved in industrial automation for 5 years. Performs tasks in robotics and mechanical engineering projects.

We Are Here to Help

Are you interested in our offer?

Write to us for a personalized consultation.

- Individual counseling

- Tailored solutions

- Quick implementation

- Experts with experience