–

Training

Cobot training courses – for our partners we conduct training courses on the operation, programming and use of available features of Doosan cobots. We conduct classes both at our headquarters – we have various models of cobots – and at the partner’s premises. The scope of training depends on the level of advancement of participants. We offer a basic scope (construction and operation of cobots, configuration of the working environment, configuration of safety settings, learning the programming environment, motion functions, loops and logic instructions) and an advanced scope (use of communication protocols, additional functions).

Machine training – a regular stage of our implementation is training before the machine is handed over for use. We teach operators how to use the equipment, the Maintenance department how to carry out service and maintenance of the machine, an important point is also training in machine safety.

Find out how we can support your business

Problems and challenges

I want to buy a cobot, but I don’t know how to program it

That’s no problem at all! Apply to us and we will show you how cobots are programmed. You will perform a number of practical exercises and learn to use their capabilities. After the training, you will decide whether you will program your cobot yourself or rely on the experience of specialists. In either case, the knowledge from the training is worth it.

In my company we have a Doosan cobot, I want to know more

If you already have a cobot and want to increase your knowledge and skills we will be happy to help you. Apply to us, we will determine the scope of training that interests you and prepare tasks to consolidate your knowledge.

I need a machine, but I don’t know if the staff can handle it

If automation is something new to you and you’re worried that implementation will be problematic, let us know during your first conversation. We’ll include extra time for training so that staff feel confident using our machines.

Step by Step

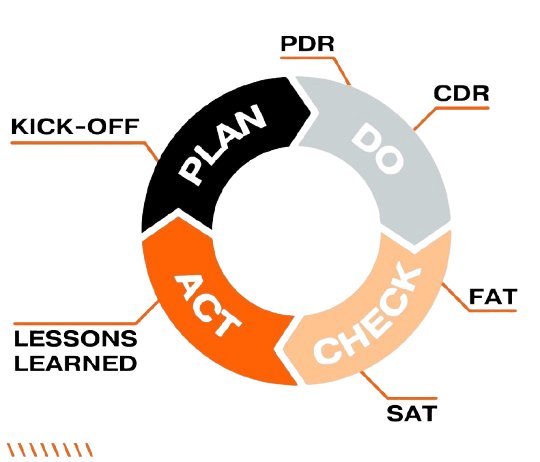

Deeply rooted in our DNA is a culture of continuous improvement reflected in the process of delivering value to our customers. We use the PDCA methodology in practice. Plan, Execute, Check and Revise – these are the stages into which we have written typical milestones in our projects.

Competitive Advantage

We are part of the renowned Transition Technologies Group, which has been creating the future of industrial technology since 1991. The group includes 21 companies, employs more than 2,280 specialists and operates from 27 offices around the world, operating with 100% Polish capital. Our mission is to provide innovative technology solutions that drive global industry growth.

- Innovation: We constantly invest in the latest technologies to keep our solutions at the forefront of innovation.

- Experience: More than three decades in the industrial technology market provide us with the knowledge and skills needed for the most demanding projects.

- Quality: We are ISO 9001:2015, ISO 27001:2013 and ISO 45001:2018 certified, confirming our commitment to the highest standards of quality and safety.

When you choose our solutions, you are investing in the future of your business – a future that is innovative, efficient and sustainable.

We work with the best:

Opinions of Our Customers

”From the very beginning of our cooperation, Transition Technologies-Control Solutions has made itself known as a reliable partner. What set them apart was their creative approach at the bidding stage. We were presented with several proposals for solutions based on which we could choose a target direction.</p>

Adam BombaProcess Manager

<p>During implementation, on the other hand, they acted with determination, solving successive problems that arose. Faced with the fact that the project was implemented in a difficult market environment, we often had to work together and develop remedies, often through compromise. Also, during the operation of the site, they reacted constructively and quickly to faults as they appeared.</p>

<p>TT-CS has proven itself as a trusted partner in challenging projects. We positively look forward to working together on future mechanical engineering projects.

Our team

Director of the robotics area at Transition Technologies-Control Solutions. A mechanical engineer by training and passion.

He has many years of experience in manufacturing process automation and project management. With the company for 3 years, he is currently in charge of business development of the robotics department and coordinating its work.

Project coordinator at Transition Technologies-Control Solutions. A mechanical engineer by training with a DIY vein.

He has extensive experience in process management. Performs tasks in automation and robotics projects.

Automation engineer at Transition Technologies-Control Solutions, a graduate of the Faculty of Mechanical Engineering at Wroclaw University of Technology.

He has been professionally involved in industrial automation for 5 years. Performs tasks in robotics and mechanical engineering projects.

We Are Here to Help

Are you interested in our offer?

Write to us for a personalized consultation.

- Individual counseling

- Tailored solutions

- Quick implementation

- Experts with experience